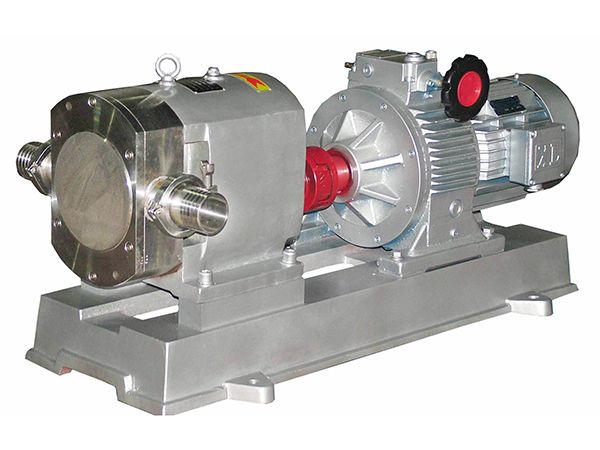

UNT-TL cam rotor pump

Product use:

It is used to suck and draw thick, granular liquid and so on. It has large suction, long life and good effect.

Main features:

1, Younaite bearing cam rotor pump and synchronous gear is in an independent and closed gear box full of internal gear oil, has a longer service life.

2, the pump shell of high precision stainless steel casting, high strength, corrosion resistance, coaxial, concentricity good, easy to disassemble and maintain.

3, the rotor is oil resistant, wear resistant and corrosion-resistant silicone coating. The advanced spiral rotor technology abroad has the characteristics of large torque, low noise and long life.

4, United cam rotor pump selection of rapid repair layout mode, all the parts can be easily disassembled, the repair becomes easy and concise.

5, United cam rotor pump shaft and transmission of material without contact, a center barrier cavity filled with oil, keep a lubricated rotor and shaft, maintains the pump cavity from erosion.

Working principle:

On the two rotor synchronous counter rotation of the rotation generated at the inlet suction cam rotor pump (vacuum), thus conveying the material to be inhaled, two rotor rotor chamber will be separated three small space, and according to the sequence of operation of ABC; operation to A, only I room filled with media operation; to B, B encloses part of the medium; running to C, B chamber and || chamber, the medium is transported to the discharge port.

Application scope:

Chemical products: fat, solvent, resin and polymer, dye, explosive.

Beverage: beer, malt juice, yeast, soda water, fruit juice concentrate, juice drink.

Food: tomato sauce, fruit and vegetable mud paste, Boudin, jam, jelly, fruit paste, flavoring agent, sweetener, yeast, salad sauce, pastry, meat, meat, a net oil and edible oil.

Cosmetics: face paste and lotion, hairstyle gel, hair dye, essence oil.

Medicine: pill paste, extract, emulsion, plaster.

Matters needing attention:

1. No waterless operation is strictly prohibited:

2. Before the pump is started, all the valve outlet valves are opened.

3, to ensure that the import is not blocked, to avoid the phenomenon of cavitation;

4, if the pump has abnormal vibration, it should stop the operation of the pump immediately and stop the cause to find out.

中文

中文 English

English